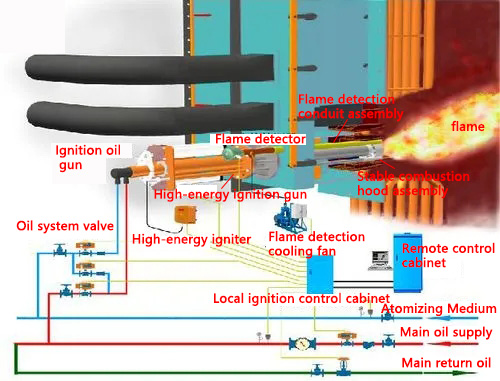

Boiler ignition system control and flame detection system

Boiler ignition system oil gun/air gun

Mainly used for the operation and control of the fuel ignition system during boiler start-up and low load stable combustion. It can achieve single step operation, programmable automatic operation, fuel pressure regulation, and provide equipment status signals according to user requirements

There are two main types of ignition oil guns:

Mechanical (pressure) atomization oil gun: This type of oil gun uses the pressure of the fuel itself to inject into the combustion chamber at a high speed, and the liquid flow is broken into droplets due to air resistance, achieving the purpose of atomization. This type of oil gun can be further divided into simple mechanical atomization oil guns and return type mechanical atomization oil guns.

Medium atomization oil gun: This type of oil gun uses the kinetic energy generated by steam (or compressed air) expansion to break the liquid into small droplets, thereby achieving the purpose of atomization. This type of oil gun can also be divided into internal mixed medium atomizing oil gun, Y-type medium atomizing oil gun, external mixed medium atomizing oil gun, etc. In addition, for inferior fuels with high wear and strong corrosion such as residual oil, coal water slurry, and waste liquid, in addition to special structural design to meet combustion atomization requirements, special materials (such as ceramics, special alloy steel, etc.) can also be selected to extend their service life.

Our company can conduct design tests based on the fuel parameters and boiler forms provided by users, and provide satisfactory solutions for different conditions and structures such as light oil, heavy oil, residual oil, steam, air, straight rod guns, and torsion rod guns. This scheme uses interface flanges to connect with the boiler body, which has the characteristics of compact structure, convenient installation, and excellent performance.

High-energy igniter

It consists of three parts: a high-energy ignition device, a high-voltage cable, and a high-energy ignition gun (including the gun head). This electric ignition device is a self-developed high-energy ignition device by our company, which has the characteristics of high discharge energy and strong adaptability to harsh environments. It can be widely used in petrochemical, natural gas engineering, coal chemical, power, metallurgy The start-up and ignition of various flammable gas venting torch devices and various gas and fuel oil industrial stoves for medical and environmental protection. According to the usage location, electric ignition devices are divided into explosion-proof and non explosion-proof types, respectively used in explosion-proof and non explosion-proof locations.

1. The high-energy igniter adopts the principle of capacitor energy storage discharge, which boosts and rectifies the power frequency power supply to obtain 2500 V DC high voltage to charge the energy storage capacitor. Using a gas discharge tube as the control switch element, the high-voltage breakdown discharge tube on the capacitor is used to quickly discharge the high-energy ignition gun head through a dedicated high-voltage cable, generating a pulse arc and igniting the flame.

2. The high-energy ignition gun is made of high-temperature resistant stainless steel, with semiconductor ceramics embedded between the two poles of the gun head. The gun body is divided into two types: rigid and flexible, and there are two connection methods between the ignition gun head and the gun body: split and integrated.

Flame detector

It is a key equipment in the Furnace Safety Supervision System (FSSS), which monitors and determines the presence or absence of flames in the furnace. It is an important component of ensuring the safe and stable operation of the boiler.

Fire detection is the "eye" of a boiler, which runs through the entire process from boiler startup to full load operation. When the entire furnace is extinguished or the burner is extinguished, the fire detector sends an alarm signal, and the system chain reacts to stop the fuel supply and prevent the accumulation of fuel in the furnace from causing boiler explosion accidents.

Detection Principle:

The

essence of the combustion of oil, coal or gas fuel is that the chemical energy

of the fuel is released in the form of electromagnetic wave, and the spectra

emitted by the combustion intermediates of different fuels are not exactly the

same. After receiving the emission spectrum of different wavelengths, the

photoelectric sensor in the fire detection probe transmits the flame detection

signal to the boiler management system or combustion controller through the

solid-state signal processing technology.

Oil flame: contains a lot of infrared, some visible light,

and a small amount of ultraviolet light; pulverized coal flame: contains a

small amount of ultraviolet light, rich visible light and infrared light; gas

flame: contains rich ultraviolet, infrared and less visible light.

Classification of flame detectors:

According to the detection components, they can be divided into infrared (IR) type, ultraviolet (UV) type, and visible light type. According to the structure of flame detection, it can be divided into integrated flame detection and probe amplifier split flame detection. According to the installation method, it can be divided into: fiber optic type (endoscope) and observation tube type (endoscope). In addition, according to industry specific requirements, there is a distinction between explosion-proof EX and non explosion-proof types.

Application field

Flame detectors are widely used in multi burner and single burner boilers in industries such as power plants, petrochemicals, steel, metallurgy, and papermaking. For example: front and rear wall opposed boilers, four corner tangential boilers, circulating fluidized bed boilers; Petrochemical heating furnace, tail gas furnace, cracking furnace, thermal oil furnace, recovery furnace, hydrogen production device; Steel blast furnace, converter, rotary hearth furnace, hot rolling process furnace, oxygen blowing device; Garbage incinerators and various industrial boilers, etc