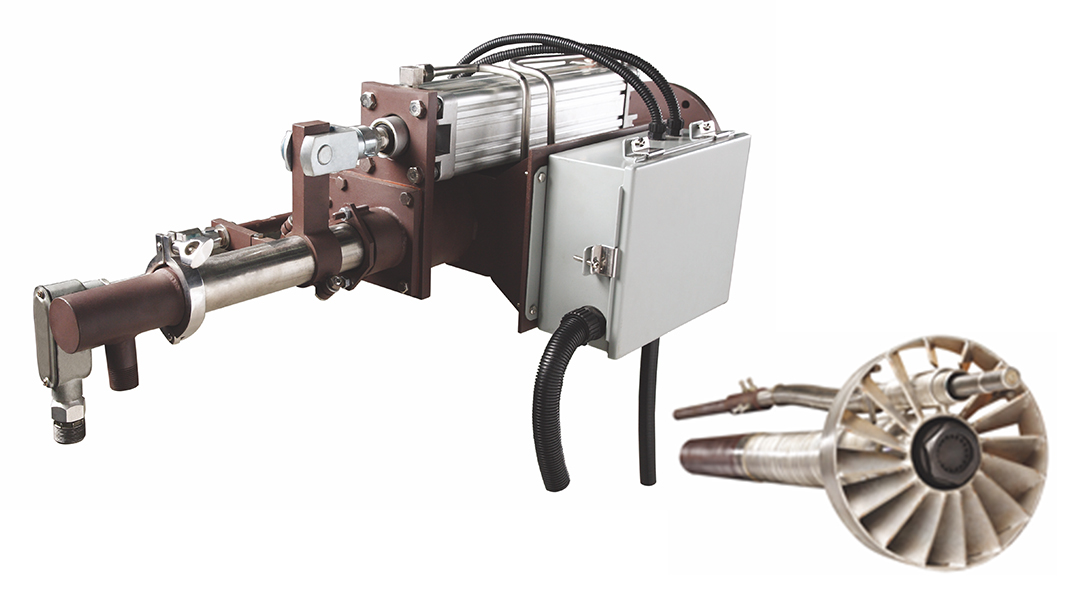

Overview:

The ignition oil gun component serves as the main burner of industrial boilers, ensuring stable combustion during boiler ignition, low load or abnormal conditions, providing energy support, and maintaining unit operation. The component mainly consists of an oil gun, a ignition gun, a high-energy igniter power supply, a high-voltage ignition cable, and a high-pressure resistant oil inlet hose. It is divided into rigid oil guns and flexible oil guns.

Product features:

1.Provide stable combustion for boilers under low load or abnormal conditions.

2.Light diesel, heavy diesel, and mixed oil can be used as fuels.

3.There are three options available: mechanical atomization, steam atomization, and air atomization.

4 .Adopting patented technology design, it can effectively avoid the jamming phenomenon of the oil gun due to dust and boiler combustion expansion.

5.The oil gun ignition system includes: the oil gun body, external conduit, igniter, ignition control cabinet, electromagnetic valve integrated control cabinet, etc.

6.An independent solenoid valve control system effectively avoids damage to the solenoid valve due to harsh environments, providing the service life of the solenoid valve.

Oil gun image

Technical parameters:

Oil gun output: 0.1-4.0 Kg/Hr (optional)

Fuel type: light oil, heavy oil

Atomization method: mechanical atomization/steam atomization

Cylinder working pressure: 0.4-0.8MPa

Fuel pressure at the inlet: 2.0-3.5MPa

Fuel and medium interface: 1NPT

Fuel viscosity: ≤ 4 ° E

Stroke of ignition gun/oil gun: 200-600 mm

Length and installation dimensions: according to customer requirements

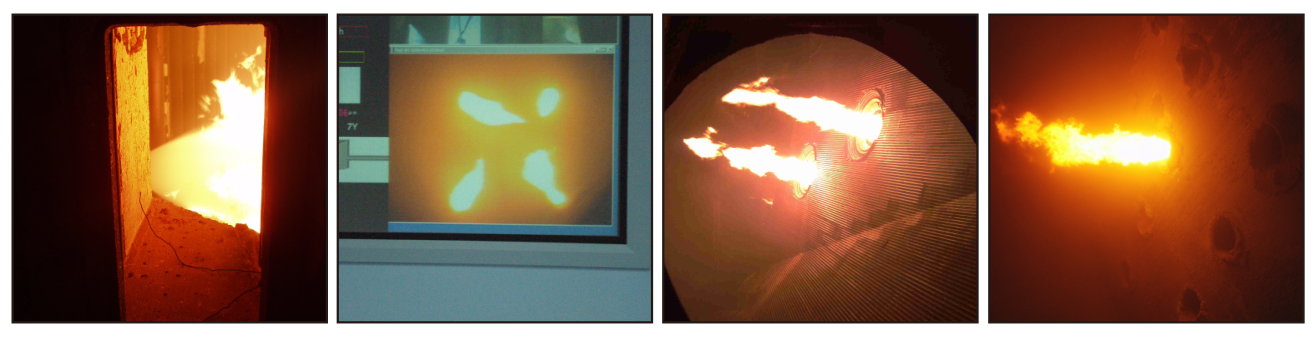

Power plant boiler ignition pictures