Overview:

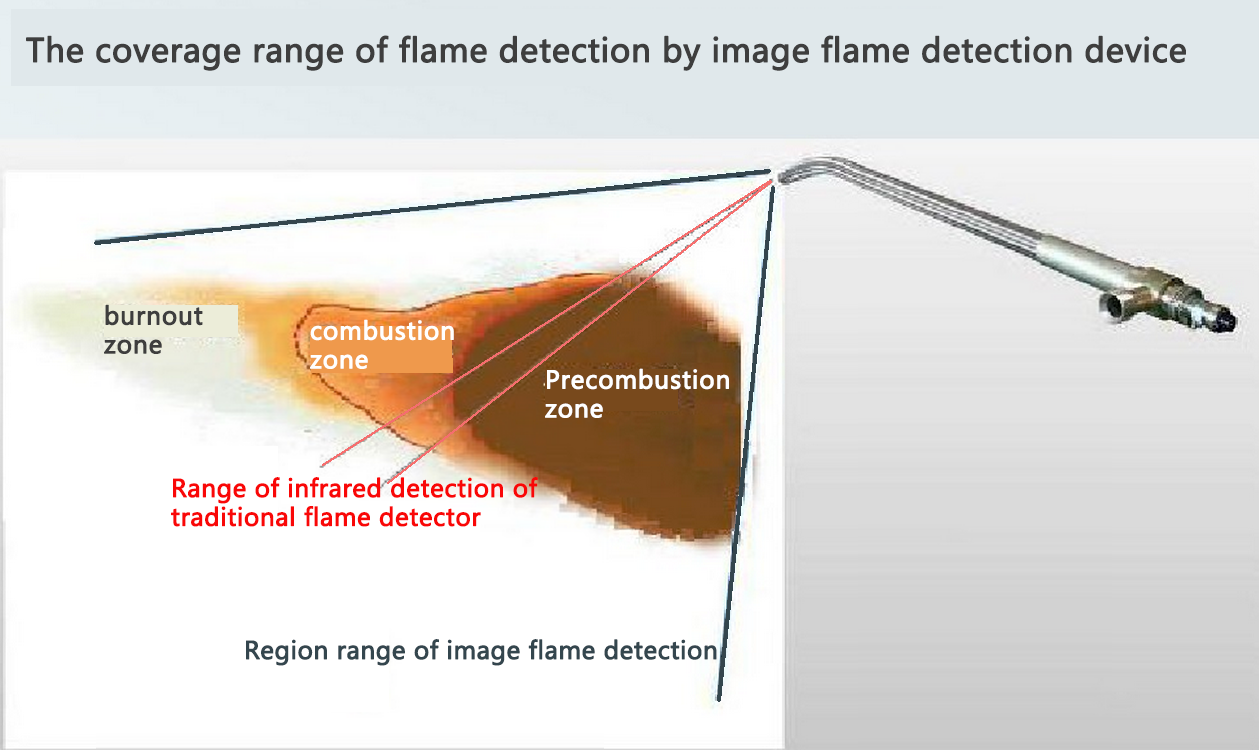

The flame image is used to monitor the flame burning status in the furnace, directly judge the fire situation in the furnace, and is not affected by fuel (coal, oil) and load changes.The equipment uses a wide-angle long focal length working lens and a color CCD camera to directly capture burner flame images (with a viewing angle of 85 ° to 90 °), providing operators with visualized real combustion image information.Boiler operators can adjust the ratio of primary and secondary air based on the flame image of the burner, which can improve the burnout rate of coal powder and boiler combustion efficiency, reduce smoke pollution, and ultimately enable it to guide monitoring and control of combustion, ensure optimal boiler operation.

Technical parameters:

The mirror surface is made of special heat-resistant glass, with a temperature resistance of 1500 ℃

CCD working voltage U=12V/DC.

Under normal working conditions of cooling air, it can withstand a temperature of 1200 ℃.

At a detection range of 1.5m or more from the testing end of the probe, the color and shape of the candlelight are not distorted.

The fifth character can be clearly distinguished at 300mm in front of the probe testing end.

The image is clear and without visible spots.

Detection screen: